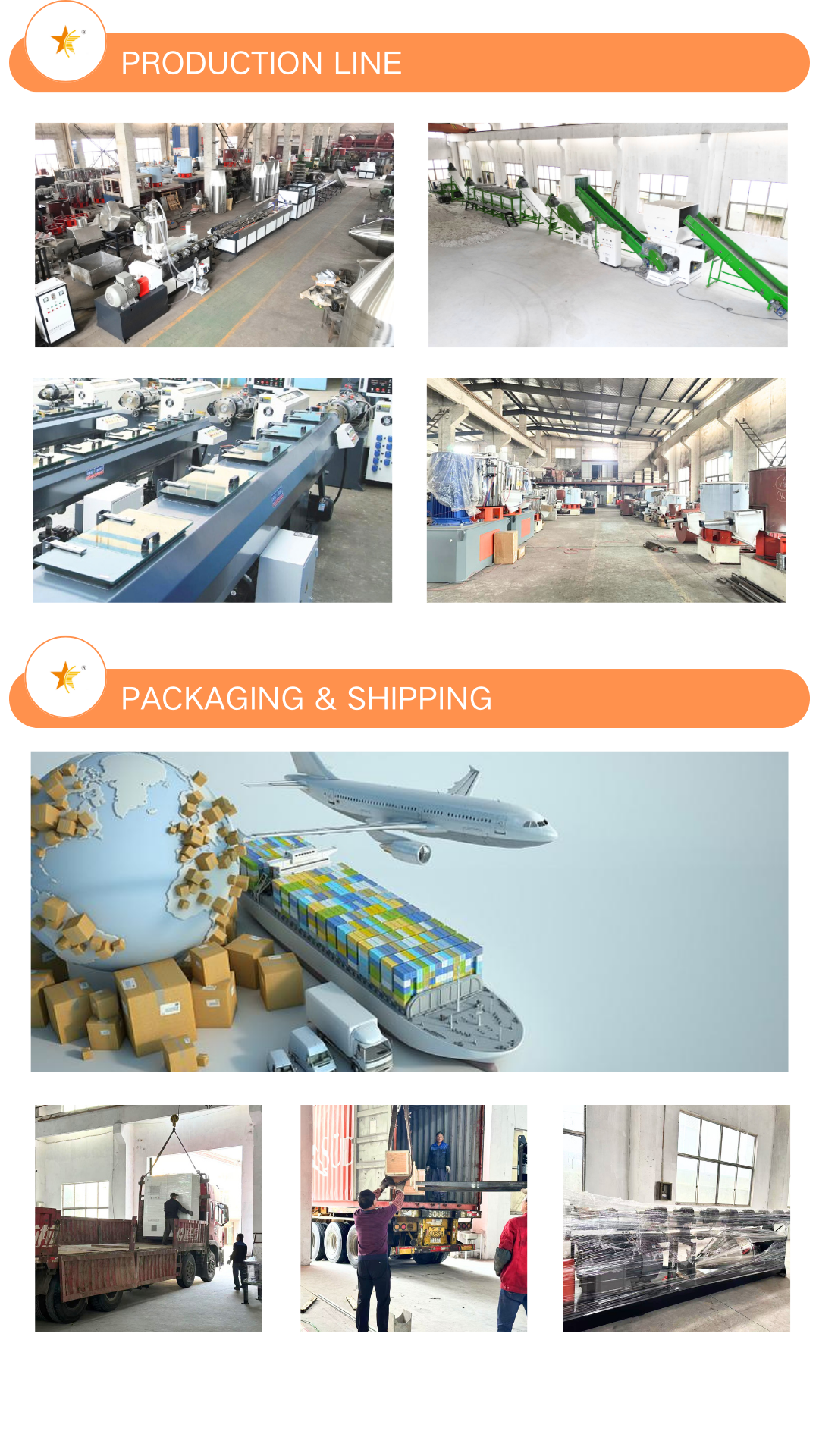

The production line can produce PVC wood-plastic door panels with a wdth of 600-1200.The equipment mainly consists of SJZ92/188 conical twin-screw extruder, calibration table, haul off, cutting machine and stacker. The equipment is advanced in configuration and well-made.The main electrical control components adopt global famous brands, such as ABB or Siemens.The extrusion system design draws on the advanced technology achievements of the same industry in foreign countries ,with high reliability and durability.

The unit adopts special-designed SJSZ 80 conical Twin-screw Extruder, and adopts imported frequency converter for governing. It adopts imported RKC temperature controller. It has advantages of wide adjustment range, high precision, convenient operation and so on. The auxiliary machine is composed of vacuum shaping table, drawing machine, cutter and turn-over frame. The unit adopts large cooling device to ensure the shaping result of door plate. The caterpillar drawing machine adopts imported reducer , motor and frequency converter. It has reasonable structure, large drawing force, steady drawing and others. The cutter has advantages of reliable and correct work, high precision of cutting and others. The turn-over frame has mobile lorry and special rubber protection layer. It has advantages of no-wearing, simple use and others. The auxiliary machine adopts programmable controller or control system made in China. The control of the whole machine is reliable and steady.

extruder model | SJZ80/156 | SJZ80/156 | SJZ92/188 | SJZ92/188 |

auxiliary model | YF800 | YF900 | YF1000 | YF1250 |

main motor | 55 | 55 | 132 | 132 |

width (mm) | 800 | 900 | 1000 | 1250 |

capacity (KG/H) | 280 | 280 | 600 | 600 |

cooling water (m3/h) | 12 | 12 | 15 | 18 |

compressed air(m3/min) | 0.8 | 0.8 | 1 | 1.2 |

The production line can produce PVC wood-plastic door panels with a wdth of 600-1200.The equipment mainly consists of SJZ92/188 conical twin-screw extruder, calibration table, haul off, cutting machine and stacker. The equipment is advanced in configuration and well-made.The main electrical control components adopt global famous brands, such as ABB or Siemens.The extrusion system design draws on the advanced technology achievements of the same industry in foreign countries ,with high reliability and durability.

The unit adopts special-designed SJSZ 80 conical Twin-screw Extruder, and adopts imported frequency converter for governing. It adopts imported RKC temperature controller. It has advantages of wide adjustment range, high precision, convenient operation and so on. The auxiliary machine is composed of vacuum shaping table, drawing machine, cutter and turn-over frame. The unit adopts large cooling device to ensure the shaping result of door plate. The caterpillar drawing machine adopts imported reducer , motor and frequency converter. It has reasonable structure, large drawing force, steady drawing and others. The cutter has advantages of reliable and correct work, high precision of cutting and others. The turn-over frame has mobile lorry and special rubber protection layer. It has advantages of no-wearing, simple use and others. The auxiliary machine adopts programmable controller or control system made in China. The control of the whole machine is reliable and steady.

extruder model | SJZ80/156 | SJZ80/156 | SJZ92/188 | SJZ92/188 |

auxiliary model | YF800 | YF900 | YF1000 | YF1250 |

main motor | 55 | 55 | 132 | 132 |

width (mm) | 800 | 900 | 1000 | 1250 |

capacity (KG/H) | 280 | 280 | 600 | 600 |

cooling water (m3/h) | 12 | 12 | 15 | 18 |

compressed air(m3/min) | 0.8 | 0.8 | 1 | 1.2 |