| Availability: | |

|---|---|

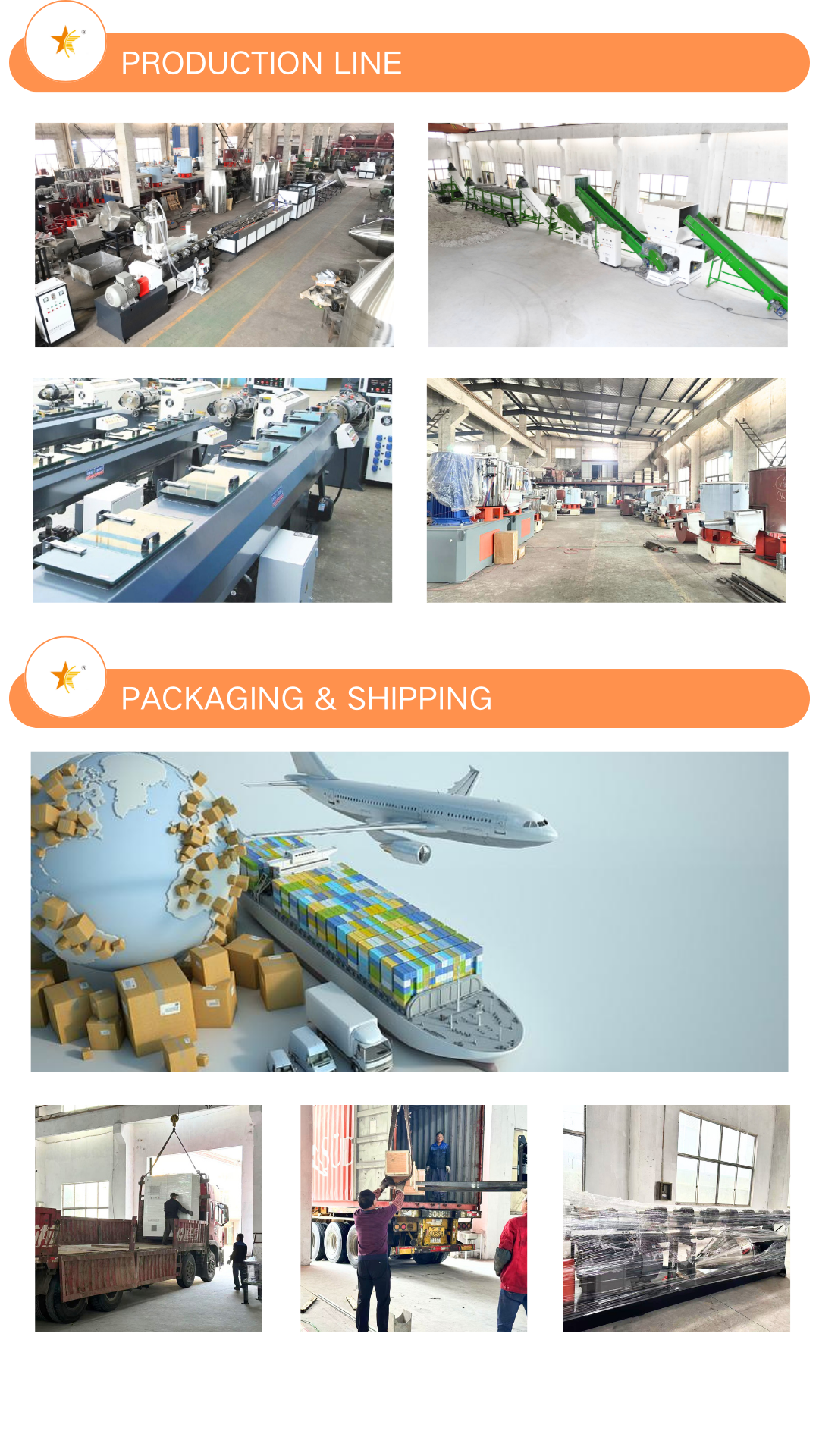

The production line is used to produce PC, PP hollowness grid boards. The board is popularly used to buildings, decoration, advertisement ornament, sound insulation on road and packaging,Construction of sunroof in buildings ,halls, shopping center ,stadium ,public places of entertainment and public facility.

Ring shield of bus stations ,garages, pergolas, corridors. Transparent shields for security forces in nursery schools airports, factories. The PP hollowness board can replace the paper packaging canton with the advantages of light weight, high strength, damp-proofing and corrosion-resistance. The width of the board is 1220-3000 mm; thickness is 2-16mm.

Application of the PP Hollowness Grid Board:

The PC hollowness grid board can be processed into turnover case, packaging case, clapboard, lining board, backing board and pallet, etc, due to its advantages of light weight, high tenacity, damp proof, environmental performance and secondary processing.

It is widely used in such fields as the electron, household electrical appliances, packaging,- machinery, postal, food, medicine, pesticide and advertisement decoration, etc.

Also it is used as sun proof ceilings of office building, hall, market, stadium, recreation center and public facilities.

Weather shed of bus station, summer house, and corridor of lounge hall.

Safe sun-proof ceilings of airport and factories.

Velarium of modernized agriculture, livestock breeding industry and indoor swimming pools.

Noise barrier on high way and elevated road in cities.

Advertisement billboard, lighting box and exhibition decoration.

Partition wall between office and living room, and between bathroom and toilet.

Model of extruder | PC SJ-150/36 | PC SJ-120/36 | PP SJ-120/30 | PP SJ-90/30 | |

Power of main motor | 185KW/22KW | 132KW/18.5KW | 132KW | 75KW | |

Product width | 1600-2100mm | 1300-1600mm | 1600-2100mm | 1300-1600MM | |

Product thickness | 2-25mm | 2-20mm | 2-12mm | 2-12MM |

Equipment List

| No | Device Name | Qty |

| 1 | Vacuum Loader& Dryer | 1 |

| 2 | SJ120/35 Single Screw Extruder | 1 |

| 3 | Screen Exchanger& Melt Pump&Mould | 1 |

| 4 | Calibration Table | 1 |

| 5 | First Haul Off Unit | 1 |

| 6 | Annealing Tank | 1 |

| 7 | Forced Cooling Device | 1 |

| 8 | Second Haul Off Unit | 1` |

| 9 | Corona Treatment | 1 |

| 10 | Blade Type Cross Cutting Device | 1 |

| 11 | Stacker& Transfer Table | 1 |

| 12 | Electrical Set | 1 |

Remarks: all information above is only for reference; please gather the exact data by contacting us.

The production line is used to produce PC, PP hollowness grid boards. The board is popularly used to buildings, decoration, advertisement ornament, sound insulation on road and packaging,Construction of sunroof in buildings ,halls, shopping center ,stadium ,public places of entertainment and public facility.

Ring shield of bus stations ,garages, pergolas, corridors. Transparent shields for security forces in nursery schools airports, factories. The PP hollowness board can replace the paper packaging canton with the advantages of light weight, high strength, damp-proofing and corrosion-resistance. The width of the board is 1220-3000 mm; thickness is 2-16mm.

Application of the PP Hollowness Grid Board:

The PC hollowness grid board can be processed into turnover case, packaging case, clapboard, lining board, backing board and pallet, etc, due to its advantages of light weight, high tenacity, damp proof, environmental performance and secondary processing.

It is widely used in such fields as the electron, household electrical appliances, packaging,- machinery, postal, food, medicine, pesticide and advertisement decoration, etc.

Also it is used as sun proof ceilings of office building, hall, market, stadium, recreation center and public facilities.

Weather shed of bus station, summer house, and corridor of lounge hall.

Safe sun-proof ceilings of airport and factories.

Velarium of modernized agriculture, livestock breeding industry and indoor swimming pools.

Noise barrier on high way and elevated road in cities.

Advertisement billboard, lighting box and exhibition decoration.

Partition wall between office and living room, and between bathroom and toilet.

Model of extruder | PC SJ-150/36 | PC SJ-120/36 | PP SJ-120/30 | PP SJ-90/30 | |

Power of main motor | 185KW/22KW | 132KW/18.5KW | 132KW | 75KW | |

Product width | 1600-2100mm | 1300-1600mm | 1600-2100mm | 1300-1600MM | |

Product thickness | 2-25mm | 2-20mm | 2-12mm | 2-12MM |

Equipment List

| No | Device Name | Qty |

| 1 | Vacuum Loader& Dryer | 1 |

| 2 | SJ120/35 Single Screw Extruder | 1 |

| 3 | Screen Exchanger& Melt Pump&Mould | 1 |

| 4 | Calibration Table | 1 |

| 5 | First Haul Off Unit | 1 |

| 6 | Annealing Tank | 1 |

| 7 | Forced Cooling Device | 1 |

| 8 | Second Haul Off Unit | 1` |

| 9 | Corona Treatment | 1 |

| 10 | Blade Type Cross Cutting Device | 1 |

| 11 | Stacker& Transfer Table | 1 |

| 12 | Electrical Set | 1 |

Remarks: all information above is only for reference; please gather the exact data by contacting us.

content is empty!